|

||

Skin packaging Skin Packaging. Is the most fast, flexible and practical "Card Display" packaging.

FILPACK has the expertise and knowledge to manage your complete skin packaging project from start to finish. All you need to do is supply us with the product and artwork and we can do the rest. It is also best suited for smaller products that are relatively lightweight but can be used for larger items as well. Skin packaging involves placing a product - or in set - on a substrate material such as special cardboard. Heated plastic film is draped over the product and the substrate, and a vacuum draws the film down tightly to the board and around the product to make a secure and attractive package.

For the skin package, we use three components:

Heat sealable PE film, as an environmentally friendliest material, in 0,130 mm thickness

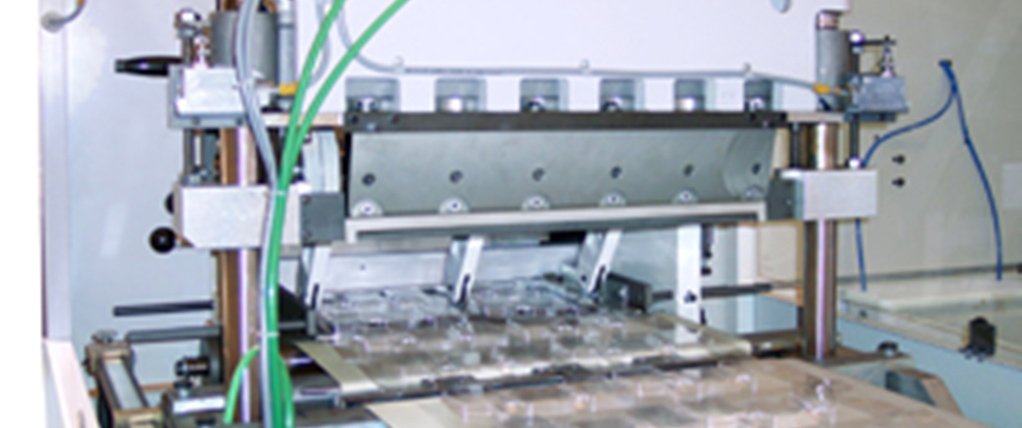

The board is placed on a vacuum platen and product is placed on the board. Film is held tightly in place by a clamping frame, directly below the heater. At the beginning of the packaging cycle, the film is heated, and then the clamping frame is lowered, draping the heated film over the product and board. The film is then drawn down by vacuum, resulting in a tight covering over the product and card. The hot plastic melts the adhesive, and the paper and plastic are bonder together. Skin packaging is used for visual carded display, the packs are typically rack hung, highly consumer appealed by 3-D presentation, with easy opening features and often a cost-effective alternative to blister packs. Throughput may be faster or slower than alternative methods depending on the product size, configuration and volume. Product instructions, pictures, warnings, warranties, as well as prices and sizes can be printed on the back and front of cardboard. Skin packagingproducts |

||

.jpg)