|

||

PS.PS. Product Profile:

Polystyrene has characteristics of high strength, large rigidity, good transparency, light specific gravity. It is nontoxic, smallness and environmentally friendly and is widely used for medicine tray, injection trays and various thermoformed food trays. Modern polystyrene packaging has long been preferred material of the foodservice industry because it insulates better, keeps food fresher longer, creates outstanding gloss, costs less than alternative products and uses less resources. With today’s growing concerns about the environment and climate change, polystyrene packaging solutionsare becoming more recognized as environmentally preferable for many reasons including their lightweight. Some of film’s properties include:

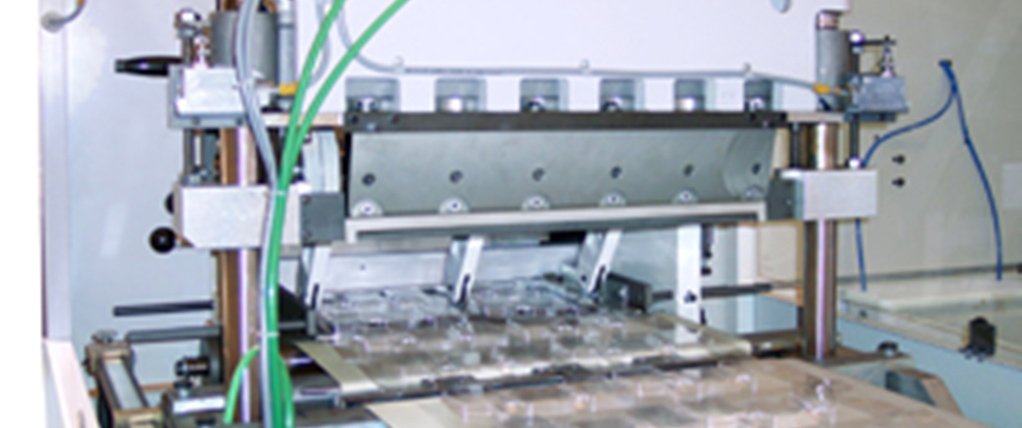

• crystal clarity and sparkling gloss, • excellent moisture vapour transmission rates for food protection and product appeal, • high strength and rigidity which allows stacking without fear of collapse or damage, • optimum machining and high speed forming, • optional silicone coating permits easy mould release and de-nesting of thermoformed trays. BOPS is produced by completely answering the FDA and EEC requirements for food and medical contact. Foil thickness varies with less than 5%. Its surface is silicone or anti-fog coated, which enables printing or metallization. The offered colours are: clear, white, yellow, blue, green, brown, black, gold or silver metalized.

BOPS. Product Profile: Superior clarity, sparkle and gloss. Hardly breakable, high impact strength and excellent hardness. Excellent stiffness. Limited taste/odor transfer. FDA compliance. Recyclability. Non toxic, odourless, smallness, low density. Guarantees dimensional stability, easily processed. Excellent appearance. BOPS appliance: Food and beverage industry. Medical and cosmetic industry. Electronics and etc. PS. |

||